Millstone Outfall Fish Barriers Restoration

Waterford, Conn.

Award of Merit

Owner: Dominion Energy Nuclear Connecticut

Lead Design Firm: Sargent & Lundy LLC

General Contractor: Cianbro Corp.

Subcontractors: Underwater Construction Corp. (Dive Support)

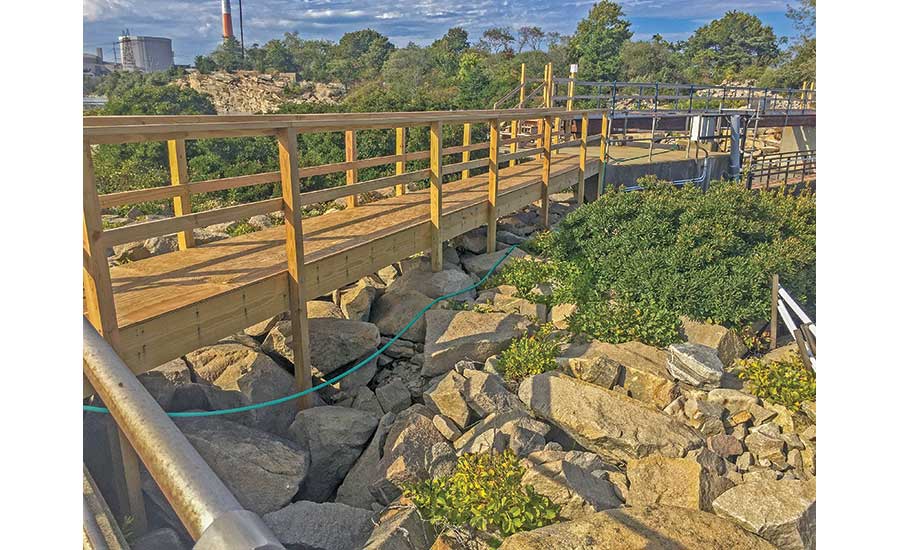

To avoid massive fish kills in the event of an outage of the nuclear power plant’s two pressurized water reactor units, the project team replaced two deteriorated steel fish barriers that keep marine life out of the facility’s water discharge canal.

Because the schedule did not allow for rework in this 97% self-performed project, the project team says it developed a plan to preassemble structures on shore and set each one as a single unit.

The plan required engineered shoring and rigging assembles to slide the 50,000-lb, top-heavy structures from a vertical position into slots in the concrete abutments with extremely small tolerances.

To accomplish this, the in-house design team engineered custom rigging attachments and an adjustable rigging scheme with clamps fabricated to provide a pick point for any necessary adjustments.

Thanks to planning and collaboration, the project team says it delivered the two barriers ahead of schedule.

While casting the concrete, the team says it utilized Spin Screed, a product that uses small plastic chairs, eliminating the use of a screed rail system with a 2-in.-dia pipe. By utilizing the Spin Screed system, the team says it improved operational efficiency and eliminated ergonomic hazards associated with the labor-intensive setup typically used for casting concrete.

Regulated by the U.S. Nuclear Regulatory Commission, the project was held to “extremely high quality standards,” the team says.

Post a comment to this article

Report Abusive Comment